Alignment service

for Paper/Board/Tissue Machines

Skillful and experienced staffs

High quality and reliability

Accurate equipments and tools

High quality and reliability

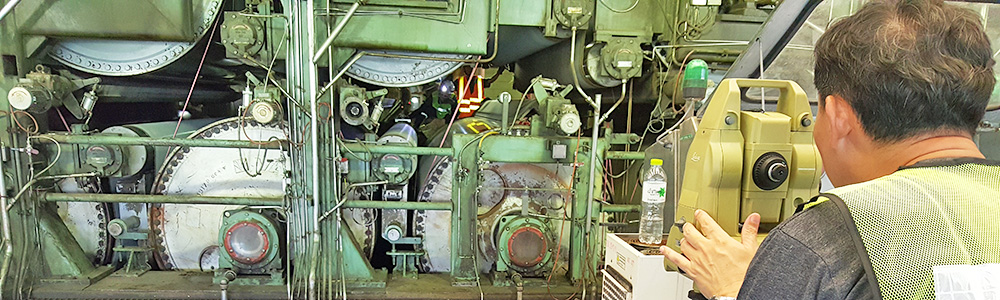

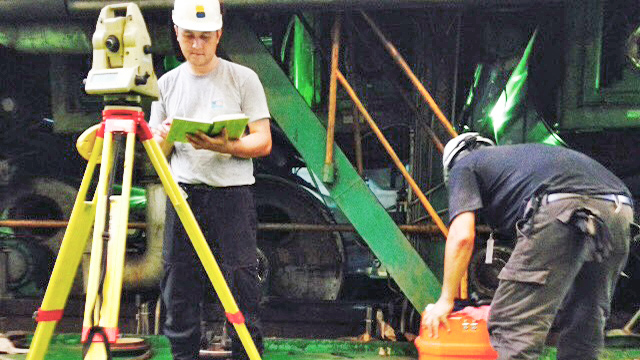

The achievment of alignment services are for example; better dewatering, better formation, better paper profile, better production line runnability, lower vibration and longer service life time of parts and components e.g. roll cover, fabric. Basically, all machine components need to have a good alignment but typically the rolls and dewatering elements play significant role on it. PMPRO specialists, equipped "Wild N3" leveling instrument and "Leica TCA1800" total station, have been on alignment service kind of work even before finding of PMPRO company.

Survey inspection includes; => Vertically or "Level" - Vertical inspections determine a components' level condition. The level relates to the earth. => Horizontally or "Square" - Horizontal inspections determine a components' perpendicularity relating to the machine datum line which is usually shifted to the tending side as reference pins. // It is wise to obtain a good picture of total alignment before making any adjustments. A survey inspection usually obtains this information. Based on the inspection results, the rolls and components could then be realigned and re-confirmed by measurement after adjustment.

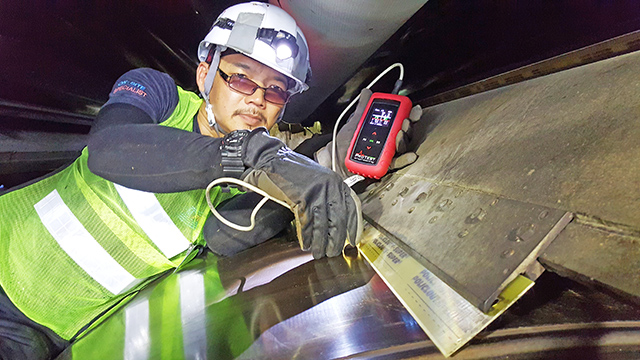

Target of this service is to check and measure doctor blade alignment and contact angle to find out the existing condition of the doctor blade. Scope of this service is to measure doctor blade contact angle and alignment with new blade. The realignment will be done by adjusting screw and/or shimming plate. PMPRO is using very accurate angle meter which can be set roll diameter compensate value by 10mm step. The angle meter will show both angle and alignment value. Adjustment is done by considering both holder alignment and its blade angle alignment. .