Headbox service

for Paper/Board/Tissue Machines

Skillful and experienced staffs

High quality and reliability

More than 100 references

Local and abroad

The headbox performance shows significant role in making a good quality of products. Maintaining and improving headbox performance is thus very important. And by maintaining the headbox performance, you can get benefit for e.g. improved dry-weight or bone-dry profile, better quality of product, better production line runnability.

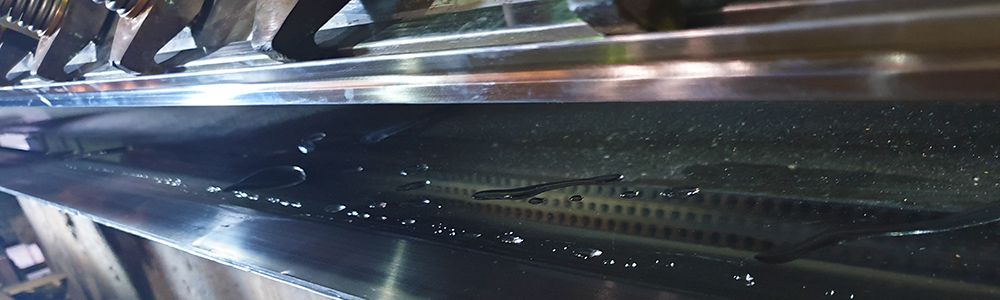

Headox performance check-up by PMPRO specialists to reveal; existing slice opening profile in related to the paper profiles/ change, deformation and damage of the top and bottom lips/ headbox alignment and control of the jet impingement/ functioning of the slice control system/ general condition and cleanliness of the slice flow surfaces/ spare parts needed for headbox reconditioning. Headbox conditon test takes 12-14 hours shutdown. The slice opening is zeroed after the test.

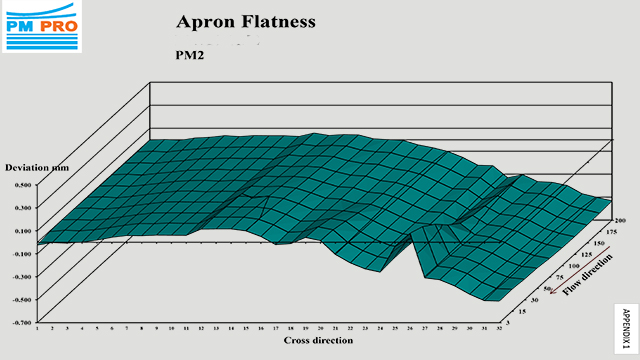

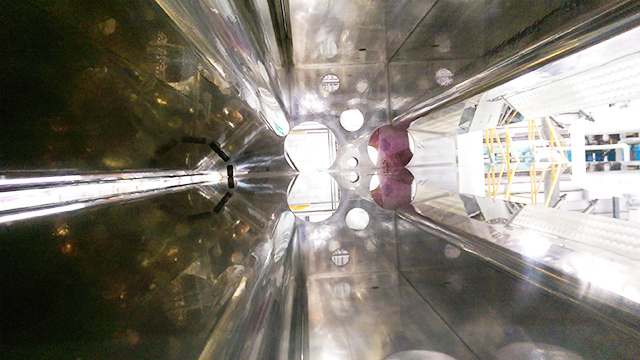

Based on headbox testing result, the headbox reconditioning tasks and the time-need for the actions are verified. Typical scope of headbox reconditioning are for example; apron recondition by grinding and polishing/ headbox realignment/ still chamber polishing/ realignment of top slice beam relative to apron/ replacement of top slice lip and its end seal/ changing of seals at side walls/ polishing of side wall flow surface/ checking of side wall end clearances and adjustment/ surface coating by non-stick polymer solutions/ realignment of breast roll and forming board. The shutdown need for headbox reconditioning is approx 2-3 days. Combining testing and reconditioning to one visit is also possible.

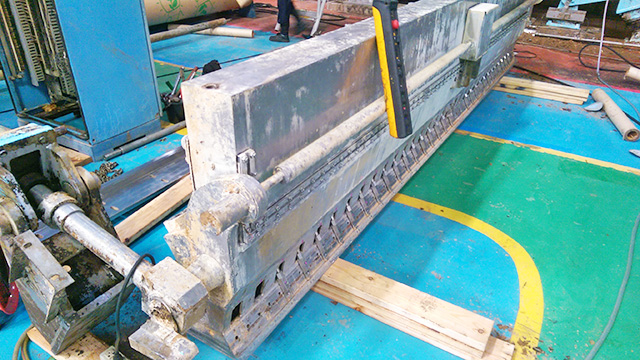

When the top beam is stuck or not align-moving, the headbox overhaul is required. The scope of work typically includes headbox testing, apron reconditioning, top slice beam movement mechanism overhaul. Horizontal transfer gears will be replaced with new gears (recommended zero clearance gears). Top slice beam movement mechanism will be overhaul and after installation, the movement test will be done over the movement range. After overhaul, the L/b ratio will be able to adjust.

Target of the service is to remove all dirtiness and hard scale then coating with non-stick polymer solution. The coating will ease of the cleaning of the headbox flow surface. Non-stick polymer will leave un-noticeable thin film on surface. This coating will form low surface energy film making the surface hydrophobic and better dirt repellant. Before coating headbox flow surface chemical resistance property will be improved by recovering of Chromium Oxide film (PASSIVATION by Nitric Acid). This surface passivation will prevent corrosion pitting of headbox flow surface.

Replaced apron could be repaired. The apron plate is sent to the workshop and put on the special support. The apron inspection and measurement are made before and after the repair. The apron repair is done by welding, grinding, bending and polishing. The repaired apron plate is sent back to the mill ready for next apron replacement.

Loosened and backlash in old style slice control system cause of poor movement and poor stability of the system thus impair the headbox performance and finally paper profile. For this kind of case, PMPRO recommend to install a new, clearance-free slice control system to the headbox.