Optimization components

for Paper / Board / Tissue machine

Sustainability solution

High quality and reliability

Increase machine efficiency / Reduce energy usage

High quality and reliability

PMPRO and APT-Daesung engineering provide optimization solutions to paper mills. The idea is to increase machine efficiency, reduce energy and enhances paper mill "sustainability".

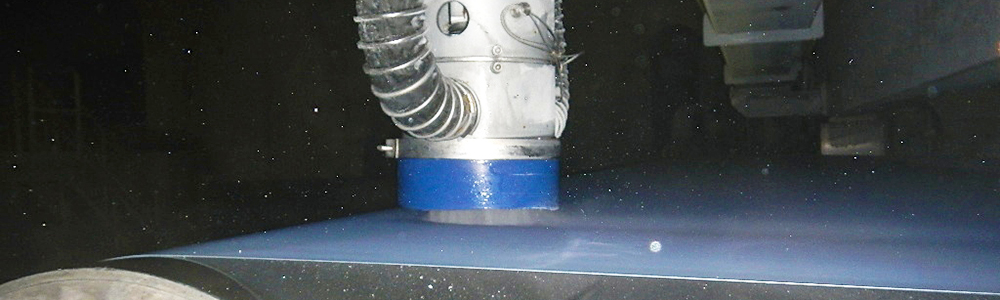

Operator Safety - hands off threading / Threading Efficiency - shortest threading time / High Reliability - continuouse repeatability / Press to Reel Section Threading Solution / Lowest Energy Consumption.

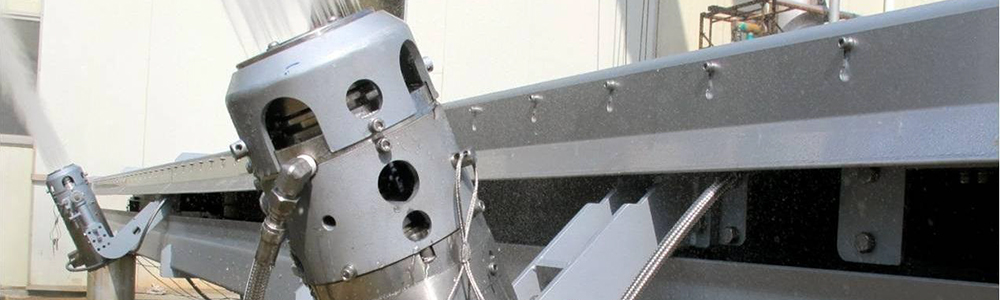

Nozzle Material : Sapphire diamond, 0.15mm diameter / Induction motor with reduction gear unit 0.75kW / High pressure pump, capacity up to 2,000 bar / Micro filter (5micron) housing, 2" x 20" L / Control unit: Control cabinet, frequency inverter (0.75kW), PLC (Siemens).

High performance shower head : Rotating head 700-900rpm, 32pcs sapphire nozzles, variable speed 0.2-1m/min, 3 variable cleaning mode / HP Pump unit : Design cap. 270 bar, stand alone solinoid valve station / 4 stages filtering system, 2 stages auto back-wash / Operating panel : Desktop PC 19" LCD monitor / Low operation cost : No need chemicals, low water consumption 15.4 ton/cleaner, low power consumption 18.7kW/1-3set / 1 pump for 3 cleaning heads / Quality improvements : Optimum wire and felt clean during running, improved CD moisture profile, reduce web-break through elimination of sticky and dirt particles / High operation efficiency : No need shutdown time for cleaning wire and felt, able to apply to all paper and tissue machines, extended wire and felt life.

Environmental contribution / Minimize bottom losses as low as 25m / Increase turn up efficiency > 99% / Operator safety - fully automatic / Return on investment less than 3 months / Fast and clean jumbo change / Water requirement : Drinking water, outlet pressure 1000-2000 bar, flow 10ml/turn up.