Superfinishing machine

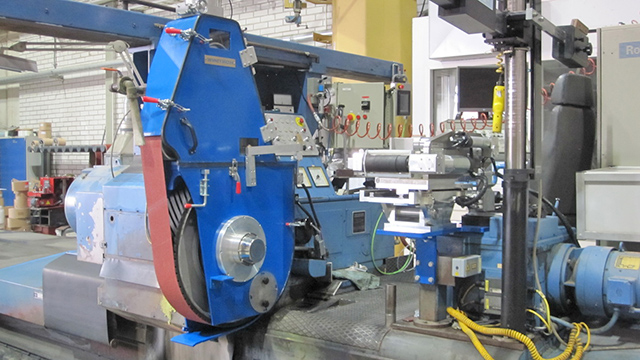

for grinding machine or on-line purpose

Effective finishing process

High quality and reliability

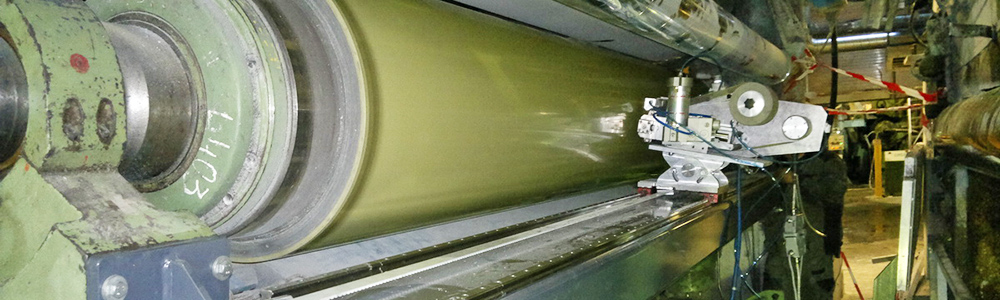

On-line superfinishing machine

High quality and reliability

Wintech deliver high-end superfinishing product.

To increase efficiency of roll grinding process. Main purpose of superfinishing are =>Totally avoid regrinding with diamond wheel of hard covered rolls like ceramic center rolls and tungsten covered calender rolls. =>Assumption is that no changes in the form of the roll have occurred. =>Make possible to roughen too smooth ceramic covered rolls. =>Rapidly remove markings of a grinding stone: last stage of grinding maybe 80% faster than with stone. / When existing finishing equipment is replaced by WinHeavy, vibration free construction enables use of 200mm wide finishing band and oscillation to enhance the process. Because of small dimensions and fully adjustable bed way package can be installed permanently to the most practical location into the roll grinder.

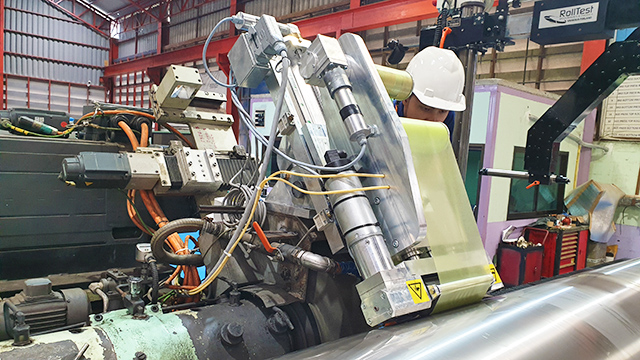

With new WinBeam in-machine finishing equipment, you get same surface smoothness for your rolls as in roll workshop but with less time and only one person needed. For all roll types and all covers. For example, dia. 600x5000mm thermo roll finished to mirror surface in only 2.5 hours, including assembly of the equipment, finishing and disassembly of the equipment. Wow!! And it's only 2 micron taken away from the surface of the roll.

WinBeamBK - Barring Killer. Designed especially to remove barring marking on a polymer covered calender roll. 2-3 times longer change interval of the roll in the machine. 2-3 times longer lifetime of the cover, only ca. 0.05mm cover ground each time. // WinBeamMC - Measurement Control. Delivered only with WinBeam, as an option. Fast: a roll is measured in a minutes! Runout, profile and pitch mark measurement. Very accurate: accuracy 1micron - 5micron - 10micron (4-2-1 sensors). Same type of measuring reports as in a roll grinder. // Other products of WinTech for e.g. WinGroove, WinDress, Winlathe, Winschleif,..